Among collectors it’s widely agreed upon that synthetic or analine dyes should not be compared to natural dyes. The passage of time and long term effects of using synthetic dye are unpredictable; change of color altogether and dyes eating into the rug are common. It’s clear to see the difference between the lustre and sheen of a naturally dyed antique rug compared to the dull uniform color that is produced through the use of chemical dyes.

There is more to the process than just mixing dye with boiling water. Each plant has its own special properties and the dyer skillfully and knowledgeably prepares the yarn accordingly. The dyers craft is an ancient one passed down through generations, father to son. He is an artisan whose traditions and secrets are highly regarded.

The sources of these natural dyes are both logical and at times surprising.

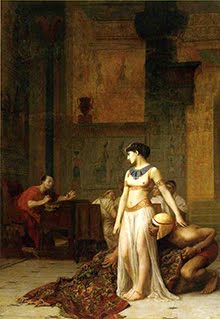

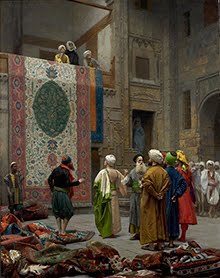

|

| The Rug Merchant by Addison Thomas Miller, below: an example of a natural red dye made from the Cochineal insect. |

Shades of red are derived from the crushed roots of madder; a climbing plant that grows wild over much of the East. It belongs to the genus Rubia whose roots contain three coloring matters, alizarin and purpurin which are both red, and xanthin which is yellow. More vivid reds were introduced in 1856 with the import of Cochineal, a female bug of the species Dactylopius coccus which lives on cactus. If you have ever marveled at the bright red color of your Campari and soda, well, thank the Cochineal!

Shades of red are derived from the crushed roots of madder; a climbing plant that grows wild over much of the East. It belongs to the genus Rubia whose roots contain three coloring matters, alizarin and purpurin which are both red, and xanthin which is yellow. More vivid reds were introduced in 1856 with the import of Cochineal, a female bug of the species Dactylopius coccus which lives on cactus. If you have ever marveled at the bright red color of your Campari and soda, well, thank the Cochineal!Saffron, tumeric, sumac and the fruit of Perisan buckthorns are used for yellows.

Greens are produced by combining indigo with yellow though Chinese green dye is obtained from Rhamnus chlorophorus, a genus of shrubs.

Different blue tones are made from the leaves of the indigo plant. The color is achieved by both the number of times the yarn is immersed in the dye vat as well as the length of dyeing time.

Tyrian purple dye is found in shellfish. Who knew?

Henna yields orange, beige is made from barley while black, brown and grey dyes are mainly made from the shells, leaves and husks of nut trees.

The dyeing process starts with the preparation of the color. Sometimes curds or sour milk is mixed into the dye to achieve lighter colors, the color is then diluted in a vat. The quantity of water varies based on the desired shade. The wool is then placed in boiling water and after being heated for the desired amount of time the wool is allowed to cool in the dye. The final stage in the dyeing process is to make the color fast. Once the carpet is ready, it is immersed in cold water to rinse any excess coloring and finally laid out in the sun to dry.

Variations in color, streaked or uneven shading known as abrash, or changes in the dye lot due to the quality of water or texture of wool, add to the charm and life of the rug. Natural dyes age in a graceful way, producing a mellow, faded color palate that remains unrivaled.